Introduction

Several electric vehicle drivers in Australia have made the long journeys away from the isolated City of Perth travelling to Darwin, Adelaide and even all the way around Australia. A few keen enthusiasts in the EV community have done an excellent job arranging 3-phase power points to be installed along these routes. While these have been much appreciated by those that have followed, many places are not well connected to the grid and the power supply is inadequate or more to the point not as reliable as required – phases are often not balanced and access is sometimes restricted. The ChargePod was developed to service these locations, with a simple easily installed skid with 50kW DC charging capability. A keen AEVA member has built a prototype unit and a fuel consumption and endurance test was undertaken.

Objectives of the test

- Check the reliability of the ChargePod over an extended multiple EV charging session

- Evaluate the equivalent diesel fuel consumption for each model of car charged

Test Outline

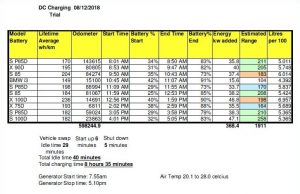

The test consisted of 10 electric cars being charged consecutively at roughly 1 hour intervals utilizing a 50kW DC charger powered by a diesel generator (ChargePod). The cars were predominately Tesla Model S and Tesla Model X which arrived with around 35% battery with a view to charging to around 85% to ensure the optimum charging range. The ChargePod was not stopped between charges but allowed to idle for the few minutes while cars changed representing what would happen in a real situation. The charge sessions were all started and stopped using the ChargeFox App.

Equipment used

- 10 full electric vehicles consisting of 6 Tesla Model S, 3 Tesla Model X and a 2018 BMW i3

- A Tritium Veefil 50kW DC charger with a Chademo and CCS2 connector

- A near new (23h) 75kVA Cummins powered generator set.

Test sequence

- ChargePod fuel tank topped up to 38mm from filler neck.

- Start charging car – record start and finish battery %, car’s average kWh consumption rate, kWh added to car, session start and finish times.

- Change subsequent cars and repeat recordings.

- Complete all 10 cars then shut down.

- Leave skid overnight to cool.

- Use mobile fuel truck with calibrated meter to refuel ChargePod to 38mm from filler neck.

- Record total fuel consumption for the test.

Calculation method

Using total kWh added to all cars divided by the total fuel consumed an average kilowatt hour per litre diesel consumed is established – this is 3.392 kWh per litre which is the ChargePod performance.

Using the lifetime average kWh per kilometre for each car (this depends on the car and the driving style and is recorded continually by the car) an individual litres diesel equivalent per kilometre for each car tested can be established

Results

- The ChargePod ran continuously for 9 hours 15 minutes and charged 10 cars without stopping.

- the generator consumed 108.6 litres of diesel.

- the total energy recorded as received by the cars battery packs was 368.4 kWh.

- the average kwhr per litre delivered to the cars by ChargePod was 3.392 kWh/l.

Diesel fuel consumption equivalents :

- BMW I3 is 4.392 L/100km

- Tesla Model S range 5.011 to 6.014 L/100km

- Tesla Model X range 5.689 to 6.957 L/100km

Conclusion :

A stand alone DC EV-charging skid powered by diesel generator for remote locations with inadequate power delivers fuel consumption results are very comparable but on most occasions better than equivalent diesel powered passenger vehicles.

Thanks to all the EV drivers who volunteered their cars on the day and most importantly to Jon Edwards who provided the venue, equipment, knowledge and can-do attitude to build the Chargepod and complete the test.

It would be even better to see what sized battery and solar array would be needed to satisfy the same situation. Initial cost would be higher, but by the time you tanker in the diesel, and consume the diesel over several years, the renewable solution should be more viable.

Given the Nullabor is a mostly sunny location, wouldn’t renewables make more sense with an EV? The idea is to get off fossil fuels, isn’t it?

Hi Jason, Solar, wind and batteries are the long term future across the Nullarbor and Northern remote locations, state owned Horizon power in Western Australia are heading in that direction now, keep in mind they have the huge finances and engineering capabilities required to do this, for roadhouse locations there is also a mindset that needs to be changed, the electricity consumption at these locations is very sporadic at the moment adding EVs to the mix will only increase the issue, there is a minimum of solar and batteries that need to be installed, there needs to be a compelling and proven financial case to shift away from a power generation system that has worked reliably for many decades.

Here in the NT Have been Designing a Solar Batt solution with a deployable 20foot container with the same 50kW charger…depending on the size of the solar, we can charge cars between 2 to 5 times a day for around $295K per site and 175kW is more like $800K which would be expandable for Trucks and Busses ..hoping to add an optus sat micro cell to every site if needed for comms/internet while charging also….sure it may be a little more up front but minimal maintenance or using a polluting fuel….how does that compare to diesel?…thanks Hunter

Hi Hunter, the batteries and solar method is the preferred option but at this stage and probably for the next two years there is is only likely to be 10-15 cars per month travel the roads the Charge pods are intended for, an outlay of less than $18,000 for a generator is not unreasonable, once the EV traffic flow increases to larger numbers then the DC charger can be transferred to a renewable source of energy and the generator re-purposed elsewhere. The batteries and solar method would benefit from state or territory government support or possibly a grant for roadhouses to install them. Please keep us up to date, the Tesla owners club are happy to promote initiatives that allow easier travel for electric vehicles.

ChargePod is a low cost way of opening up the highways for eVs to do more kms and longer road trips. Once the eVs are moving, then the business case for solar / battery will be made. Put a solar / battery system in a location and leave ChargePod there for redundancy.. ChargePod is designed to get things moving. Our leaders will spend more time and money debating this than the cost of putting a ChargePod fully installed and operational every 200km from Pt Augusta SA to Merriden WA.. I think 14 units.. at $80k installed – $1.12m.. Bingo the highway is open and eV driver spending rolling into WA coffers .. why are we waiting lets do it ..These things can be built in 3 days and dropped onsite a few days later. Anyone reading this that has done the Nullarbor in an eV – how would you like 50kw charging avaible every 200km ? I would because i3S has only 200km range 🙂

Hey, thanks for the very interesting experiment. I have worked in regional diesel power generation design and installation for the last 12 years including many remote roadhouse installs. I agree with your sentiments on cost of battery/solar. I’m interested in knowing what Diesel engine was utilised, it appears from the photos perhaps a Cummins hydra mechanical 4bt or 6bt. I’m certain a fully electronic engine powered generator would achieve even better results, in terms of usage, response to load, and emissions with minimal impact on capital outlay.

Did you do any calculations on $/kw/kwh/ including servicing of generator?

Interesting to note the Rivian has a tow to charge function which was utilised by crew on Long Way Up television show. They paid local semi drivers in remote areas heading in same direction to tow them for a period to charge.

Good work though. Very relevant

Hi Will, it was a generic 75kw generator from Able Sales. This was a good match for the 50kw Tritium DC charger. Haven’t worked out the cost for extra maintenance cost of the generator, however the more sporadic usage the higher cost per kwh delivered. This setup is certainly a stop gap measure for EV charging until larger setups are in place which cover many uses, ie EV charging plus cooking, heating, cooling etc at a venue. Basically the more a solar and battery is used on a daily basis the better its value. Regards, Rob